Certified Startup

Certified Startup

Roslab: The Unified Digital Ecosystem for Academic Robotics Labs

Roslab transforms academic robotics labs into interconnected, industry-aligned ecosystems by integrating operational management, immersive training, and industry collaboration into a single platform. It enables colleges to maximize the value of their robotics assets while providing students with industry-relevant experience through high-fidelity digital twins and standardized curricula.

1. Platform Overview

Roslab serves as the central nervous system for robotics departments, unifying:

- Lab Management & Scheduling

- Virtualized Robot Training & Maintenance Simulation

- Industry-Academia Collaboration Tools

It bridges the gap between theoretical education and practical skills demanded by Industry 4.0, creating a sustainable ecosystem for students, faculty, and robot manufacturers.

2. Key Features & Capabilities

A. Operational Management

- Unified Booking System: Students/researchers reserve lab time and specific robots (e.g., ABB Cobots, UR arms, AMRs) online.

- Live Lab Status Dashboard: Real-time visibility into robot utilization, maintenance status, and project progress.

- Maintenance Tracking: Automated service alerts, repair history, and predictive maintenance for lab equipment.

- Inventory Management: Track spare parts, consumables, and procurement needs for hardware.

B. Immersive Training & Digital Twins

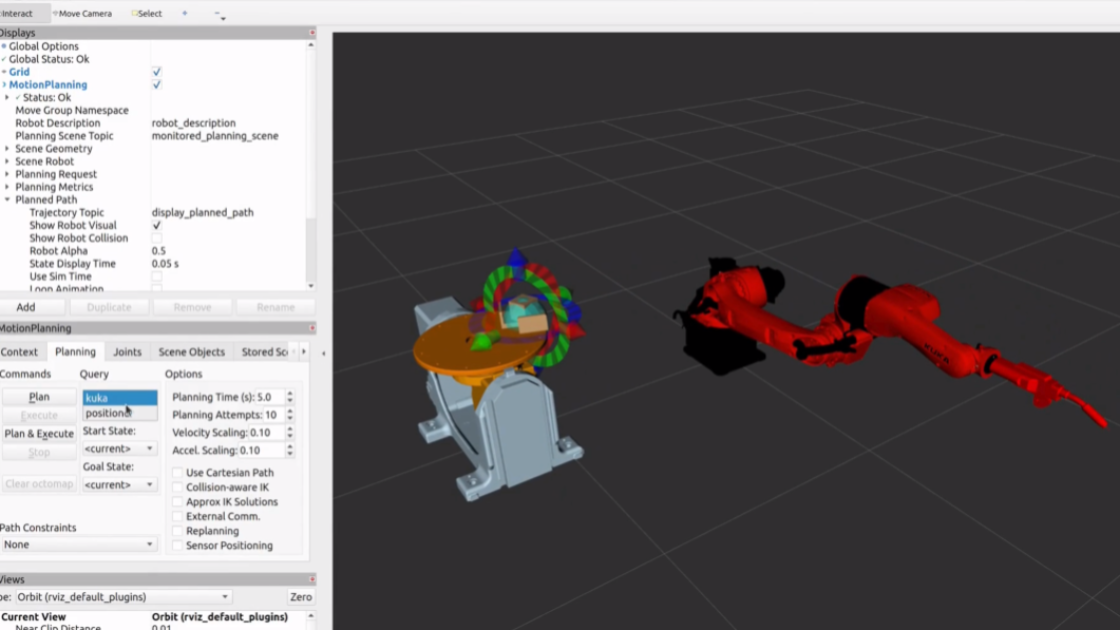

- High-Fidelity Digital Twins: Virtual replicas of lab robots (e.g., ABB Cobots, Mobile Robots) for risk-free programming, maintenance, and repair practice.

- LMS Integration: Structured courses for robot operation, programming (ROS), and maintenance, with step-by-step simulations.

- Certification Pathways: Standardized curricula for robot-specific certifications (e.g., Certified ABB Robot Programmer).

C. Industry Collaboration

- OEM Portal: Robot manufacturers (e.g., ABB, Fanuc, Universal Robots) publish digital twins, certified courses, and maintenance guides.

- Research Integration: Tools for collaborative projects between universities and industry partners.

- Placement Bridge: Industry access to student skill profiles and project portfolios.

3. Stakeholder Roles & Benefits

Stakeholder | Role & Responsibilities | Benefits

Students | Practice programming/maintenance via digital twins; book lab time; build project portfolios. | Hands-on skills without hardware risks; industry-aligned certifications.

Faculty / Lab Managers | Create syllabi; assign projects; monitor lab usage; manage maintenance. | Efficient resource allocation; data-driven curriculum updates.

Robot Manufacturers | Provide digital twins; publish certified courses; offer remote technical support. | Direct access to talent; reduced support burden; ecosystem loyalty.

Researchers | Use digital twins for algorithm testing; collaborate with industry on simulations. | Faster iteration; secure remote collaboration.

4. Technical Architecture

- Cloud-Native Platform: Accessible from anywhere, with secure role-based access.

- API Integration: Compatible with ROS, MATLAB, Simulink, and lab management systems.

- Digital Twin SDK: Allows universities to create twins of custom robots.

- Analytics Dashboard: Track student performance, equipment utilization, and maintenance trends.

5. Implementation for Academia

- Pilot Phase: Deploy with core robots (e.g., ABB Cobots, AMRs) and basic courses.

- Curriculum Integration: Map Roslab courses to Robotics/Automation engineering syllabi.

- Industry Onboarding: Invite OEMs to provide certified content.

- Scale: Expand to multi-robot collaborations (e.g., drone-AMR coordination).

6. Why Universities Shortlist Roslab

- Maximizes ROI: 24/7 virtual access to robots reduces lab congestion and hardware wear.

- Industry Alignment: Students graduate with skills directly applicable to robotics roles.

- Ecosystem Growth: Creates a circular economy where OEMs, students, and researchers mutually benefit.

- Research Enablement: Accelerates prototyping and collaboration through digital twins.

7. Conclusion

Roslab redefines academic robotics labs by transforming them into future-ready, industry-connected hubs. It addresses critical challenges in robotics education—hardware accessibility, risk-free learning, and industry relevance—making it the ideal choice for universities aiming to lead in robotics and automation engineering.